Need Racking or Storage Solutions?

Your Trusted Partner in Racking Systems

We design, supply & install all types of racking and shelving.

Maximize Space with Drive-In Racking Systems

Need to store a large number of same products in limited space? Our drive-in racking systems are engineered for high-density pallet storage and then allowing forklifts to drive also directly into the racking lanes to deposit or retrieve pallets.

This system also suitable for operations with LIFO inventory flow and high volume SKUs and its also widely used across cold storage, food distribution and manufacturing warehouses in the UAE.

What is Drive-In Racking Systems?

A Drive-In Racking System is a high density pallet storage solution where forklifts can also drive directly into the racking lanes to store or retrieve pallets. This design also eliminates the need for different aisles and maximizes cubic storage space and then crafting its suitable for warehouses storing multiple quantities of same products.

Benifits

- Forklift Access Inside Rack Lanes: Reduces aisle count for maximum storage density

- LIFO Storage Method: Ideal for bulk storage and low SKU variation

- Strong Guide Rails & Pallet Supports: Ensures safe and efficient loading/unloading

- High-Density Design: Store up to 75% more pallets than selective racking

- Custom Rack Heights & Depths: Designed to match your pallet size, weight, and handling equipment

Our Drive-In Racking Systems Products

Standard Drive-In Pallet Rack

High-density racking that also eliminates aisles, allowing forklifts to drive into storage lanes. Suitable for LIFO(Last-In-First-Out) operations.

Specs:

- Height: 4000mm – 9000mm

- Depth: 2–10 pallets deep per lane

- Pallet Width: 1200mm

- Load Capacity: 1000–1500 kg/pallet

- Rails: Galvanized support rails with adjustable levels

- Safety: Entry guards and pallet backstops

Applications:

Cold storage, food processing and batch production storage.

Heavy-Duty Drive-In Racking – High Bay

Its also designed for heavy pallets and also tall warehouse environments. Includes deeper lanes and reinforced steel structures.

Specs:

- Height: Up to 12000mm

- Depth: Up to 10 pallet positions

- Uprights: 120mm reinforced frame profiles

- Rail Thickness: 2.5mm – 3mm galvanized steel

- Load: Up to 2000 kg/pallet

- Safety: Ground rails, upright protection, guide rails

Applications:

Industrial goods, automotive parts and manufacturing supply storage.

Drive-In Racking with Pallet Guidance System

Equipped with side entry guide rails and upright guards to assist with precise forklift alignment and security.

Specs:

- Height: 5000mm – 10000mm

- Rail System: Sloped galvanized guide rails

- Aisle Entry: Floor-mounted guide channels

- Load: 1200–1600 kg/pallet

- Optional: Anti-collapse mesh, load signs, aisle labels

Applications:

High turnover storage, beverage warehouses and logistics terminals.

Drive-In Rack with Cantilever Entry Frame

Open-entry racking design with cantilever frame for easy forklift access and improved stability at entrance points

Specs:

- Entry Width: 1400–2000mm

- Upright Depth: 1000mm–1500mm

- Load: 1000–1800 kg/pallet

- Frame: Cantilever-style reinforced entrance

- Add-ons: Pallet stoppers, roof support (optional)

Applications:

Frozen storage, dairy plants and palletized bulk goods.

Customized Drive-In/Drive-Through Hybrid System

Combines both drive-in (LIFO) and drive-through (FIFO) configurations based on warehouse layout and flow requirements.

Specs:

- Height: Custom (up to 10m)

- Access: Dual entry (front and rear)

- Lane Depth: 3–6 pallets per side

- Rail System: Dual-directional pallet rails

- Load: 1000–1500 kg/pallet

- Extras: Center support columns, tunnel design

Applications:

Multi-batch operations, import/export docks and food processing.

Customizable Options

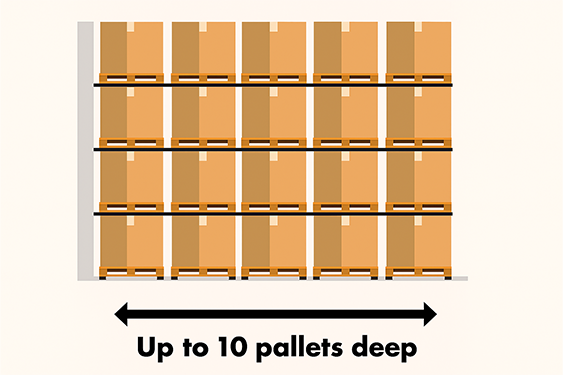

Depth: Up to 10 pallets deep

Drive-In Racking Systems deliver high density storage with personalized depth up to 10 pallets and also maximizing warehouse space and efficiency.

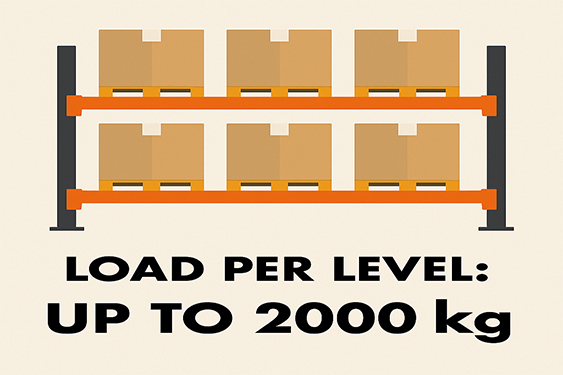

Load per level: Up to 2000 kg

Drive-In Racking Systems store pallets up to 10 deep and also supporting 2000 kg per level and also guaranteed maximum storage capacity and efficiency.

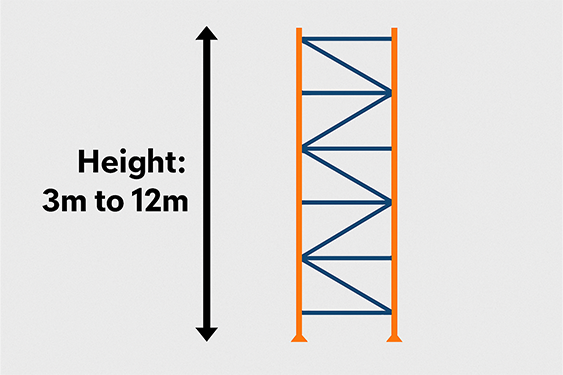

Height: 3m to 12m+

Drive-In Racking Systems provide adjustable heights from 3m to 12m+ and its suitable for optimizing vertical warehouse storage and increasing efficiency.

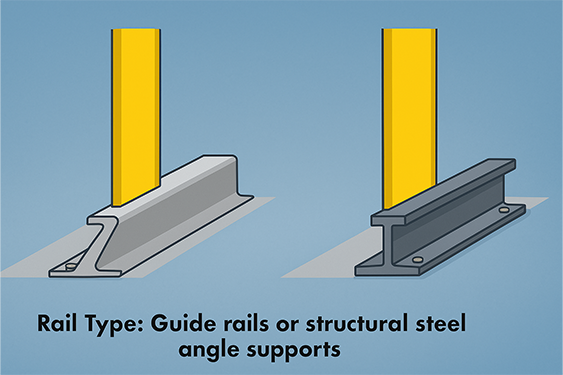

Rail type: Guide rails or structural steel angle supports

Drive-In Racking Systems use guide rails or structural steel angle supports to guaranteed precise pallet alignment and also safe load handling.

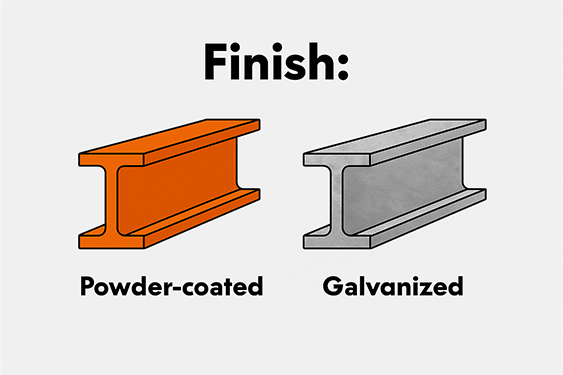

Finish: Powder-coated or galvanized

Drive-In Racking Systems provide a strong finish with powder-coated or galvanized options and also guaranteed long-lasting protection against corrosion and also heavy use.

Our Services

Free warehouse space analysis

CAD racking layout and safety review

Delivery and professional installation

Load testing and compliance

After-sales support and inspections

Why Choose Us?

We offer full-service support:

10+ years in pallet racking solutions

Local team in the UAE for faster turnaround

Fully certified materials

Customized designs for different industries

Affordable pricing with complete project support

ISO Certified

Serving All Emirates

We design, supply, and install drive-in racking in:

Dubai

Abu Dhabi

Sharjah

Ajman

Ras Al Khaimah

Fujairah

Frequently Asked Question(FAQ)

A Drive-In Racking System is a high-density storage solution that allows forklifts to drive directly into lanes to store or retrieve pallets.

It can be designed up to 10 pallets deep, depending on warehouse layout and inventory requirements.

Each level can hold up to 2000 kg, ensuring safe storage of heavy pallets.

Drive-In Racking can be customized with heights ranging from 3m to 12m+ to maximize vertical space.

You can choose between powder-coated or galvanized finishes, both offering excellent durability and resistance to wear and corrosion.